-

50 Micron Water Treatment Stainless Steel Self Cleaning Filter

50 Micron Water Treatment Stainless Steel Self Cleaning Filter

The scraper type self-cleaning filter is a kind of filter which takes the metal wedge-shaped screen as the filter element and automatically removes the particle impurities on the outer surface of the filter element by mechanical scraping. The filter is suitable for impurity separation and filtration of suspension, especially for impurity separation of viscous liquid.

Scraper type self-cleaning filter is mainly composed of filter system, filter shell and drive assembly. -

Customized stainless steel basket filter basket strainer cartridge for industrial liquid particle filtration

Basket filter is a filter with filter basket as filter element, which is used to filter particulate impurities in liquid, viscous body and gas, and protect pipes and accessories.

Basket filter is usually installed at the inlet of equipment pressure reducing valve, overflow valve and liquid level control valve for pre filtration. It is used to filter the impurities in the filter medium and prevent particulate impurities from entering the channel and causing blockage, so as to protect the equipment pipeline and accessories on the pipeline (such as water pump, valve, etc.) from wear and blockage. It is widely used in petroleum, chemical, pharmaceutical, food and other industries -

DN300 Chemical latex filtration Stainless Steel Housing Basket Filter

The filter basket of basket filter is different according to the inlet and outlet design of filter medium. The high inlet and low outlet design adopts flat inlet filter basket, flat inlet and flat outlet design and inclined inlet filter basket design.

-

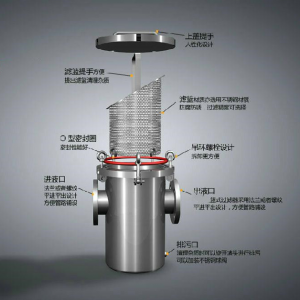

Candle Cluster Filterhousing Chemical Precision Liquid-Solid Filtration

Cluster filter is a kind of precision clarification filter with closed filtration, which adopts the design of back blowing and slag removal and integrates the tubular filter element on the liquid collecting pipe. It is also commonly referred to as tube bundle filter or candle filter.

A tubular filter element is integrated inside. Shape the filter cake to a certain thickness, and after the pressure difference reaches the preset value after filtration, discharge the filtered clarified liquid through the outlet, then introduce gas to blow back the filter cake from the filter element, and then clean the filter element for the next filtration cycle. -

304 316L Material 25~3000 μm Filter Rating Petrochemical latex Liquid Solid Filtration Basket Filter

Basket filter is usually installed at the front end of the pipeline to remove impurities or solid particles in the fluid, so that machinery and equipment (including compressor, pump, etc.) and instruments can work and opernormally, for stabilizing the process and ensuring safe production.

-

-

basket strainer basket filter housing experienced export factory

basket strainer basket filter housing experienced export factory Basket strainer can remove solid particles from liquid, and its solid impurity particles are blocked in the filter basket. Clean liquid flows out through the filter basket. When cleaning is needed, take out the filter basket and reload it after cleaning. It is convenient to use and maintain. Material:stainless steel, low carbon steel and other material as required Feed port and discharge port: high-in low-out, level-in an... -

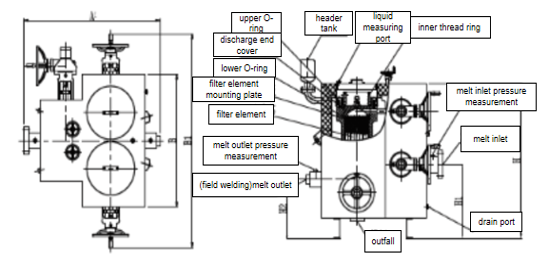

Customized vertical melt filter spinning melt filter for plastic line

Customized vertical melt filter spinning melt filter for plastic line

The vertical melt filter is mainly used to filter polymer. Good quality melt filter can greatly improve the quality of spinning ,prolong the life of spinning pack and reduce the cost.

Vertical melt filter features:

Adopting the process route of lower inlet and upper outlet, outer inlet and inner outlet, exhaust and discharge, sewage and slag discharge, no dead angle, rapid passing, short residence time, ensuring the filtering effect, the valve seal adopts Co based cemented carbide, so that the sealing performance is better and the service life is long.Vertical melt filter application scope:

Pet spinning short fiber and polyester zipper monofilament, plastic .

steel belt, plastic granulation and other fields.Our service:

• We design, engineer and manufacture and customized the production line for every customer.

• Choosing the right solution: In plastics manufacturing, process is everything. We carefully evaluate each project’s requirements, weigh the options and recommend the best solution for the client.

• Training & Development: we offer extensive start-up assistance, comprehensive training.

• Support: We support the client in all the stages of the project life cycle, as well as the constant spare parts supply in a time efficient manner. -

Stainless steel bag filter housing bag cartridge filter for petrochemical industry

Stainless steel bag filter housing bag cartridge filter for petrochemical industry

Origin:China

Material:A3,#20 steel,SS304(for fresh water),SS316(for sea water)

Filter accurancy:0.5-1000micron

inlet and outlet:1-14inch or customized

bag filter housing working principle

Bag filter is a widely used for liquid filtration,it can remove the particles of different size from liquid,in order to achieve liquid filtration,purification,separation,recovery purposes.It consists of three parts:bag housing,supporting basket and filter bags.According to flow rate,you may use multiple bags in a bag housing.First,the liquid enter into the housing from the inlet,which may placed in the side or on the top,and then flow into the filter bag which is braced by basket.Due to the impact pressure of fluid,the bag will extend and the liquid get evenly filtered through the bag and flow out of the outlet pipe.Impurities are trapped in the bag,the filtration process is complete.When you replace or clean the bag,just simply loosen the bolt,rotary hand wheel lifting the lid,and get the bag.

bag filter housing festures:

Bag filter is a versatile filter equipment with simple and flexible operation, energy saving, high efficiency, closed work and strong applicability.

The bag filter is supported by metal net basket inside, liquid flows in from the inlet, and then flows out from the outlet after filtering by the filter bag. Impurities are intercepted in the filter bag. Can be used after replacing the filter bag.Bag housing Internal structure

1. Each bag has a separate locking device with no side leakage opportunities.

2. Integrated design of precision without distortion.

3. Integrated precision with lifting device.

4. O-ring seal, high-strength and quick bolts.Filter bag material

bag filter housing application:

1. Food and beverage industry: beer, wine, wine, sake, liquor, wine, fruit juice, bottled water, tea drinks, soy milk, syrup, dairy products, food additives, water filtration to clarify the process and CIP.

2. Petrochemical industry: all kinds of lubricants and oil, glue, chemical fiber manufacturing process of various solution was filtered.

3. Oil and gas industry: amine desulfurization, dehydration flux filter, oil field water, completion fluid filtration.

4. Car paint, painting industry: paint, electrophoretic paint, pre-treatment fluid, paint and paint raw materials and solvent filtration

5. Textile, printing and dyeing, paper making industry: spinning liquid, dyes, flux, water, additives, adhesives filter.

6. Edible oils and soap industry: polishing purification of edible oil, soap raw materials and water filtration.

7. Pharmaceutical industry: a variety of pharmaceutical intermediates, pharmaceutical raw materials, solvent filtration.

8. The electronic and electroplating industry: a variety of plating solution and water filtration.

9. Machining industry: a variety of cutting fluid, coolant and cleaning liquid filtration.

10. Other liquid filtration. -

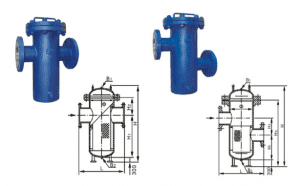

Stainless steel basket filter China basket filter housing direct factory

Stainless steel basket filter China basket filter housing direct factory

Component:

mainly composed of connecting pipe, filter body, filter basket, flange, flange cover and fastener.characteristic:

high design pressure,

filter rate≥40microns

Large filtration area, which can meet the conditions of large flowworking principle:

When the liquid enters the filter basket through the cylinder, the solid impurity particles are blocked in the filter basket, while the clean fluid passes through the filter basket and is discharged from the filter outlet. When cleaning , loosen the plug at the bottom of the main pipe, drain the fluid, remove the flange cover, and then install it again. It is very convenient to use and maintain.Application scope:

1. Chemical industry: production of petrochemical

and latex products.

2. Dairy products, beer, drinks, etc

3. Low temperature materials in refrigeration, such as

liquid methane, liquid ammonia,Liquid oxygen and

various refrigerants.

4. High efficiency filters of various special processes. -

Stainless steel 10micron filter housing bag filter housing direct factory

Bag filter is a kind of multi-purpose filtration equipment with novel structure, small volume, simple and flexible operation, energy saving, high efficiency, closed work and strong applicability.

-

Filter housing bag filter housing direct factory

Bag filter is a kind of multi-purpose filter equipment with novel structure, small volume, simple and flexible operation, energy saving, high efficiency, airtight work and strong applicability. Bag filter is a kind of pressure filter device, which is mainly composed of three parts: filter container, supporting net and filter bag. When the bag filter is used to filter the liquid, the liquid enters from the liquid inlet on the side or below of the filter container, and rushes into the filter bag from the top of the filter bag supported by the net blue. The filter bag is expanded due to the impact of the liquid and the uniform pressure surface, so that the liquid material is evenly distributed on the inner surface of the whole filter bag, and the liquid passing through the filter bag is along the metal support net blue wall. It is discharged from the outlet at the bottom of the filter. The filtered particles are trapped in the filter bag to complete the filtration process. In order to keep the filter smooth and accurate and ensure that the downstream liquid is not polluted, the machine should be shut down after a period of operation, the end cover of the filter should be opened, the intercepted matter and the filter bag should be taken out together, and the new filter bag should be replaced. The replacement period depends on the actual situation. Different filter precision depends on different filter bags.

Material: SS304; 316; 316L, carbon steel

Surface treatment: mirror polishing, sandblasting, etc.

Import and export form: flange, quick mounting, thread.

Other specifications can be customized.

The theoretical flow rate is the reference value of water treatment. The actual value will vary with the viscosity, impurity content and pressure difference of the liquid.

Product features:

1.Bag filter has the advantages of large capacity, small volume and large capacity.

2.Based on the working principle and structure of the bag filter system, it is convenient and fast to replace the filter bag, and the filter is free of cleaning, saving labor and time.

3.The side leakage rate of filter bag is small, which effectively ensures the filtration quality.

4.The bag filter can bear more working pressure, with small pressure loss, low operation cost and obvious energy saving effect.

5.The filtration accuracy of the filter bag has been continuously improved, and now it has reached 0.5um.

6.The filter bag can be used repeatedly after cleaning to save cost.

7.Bag filter has a wide range of applications, flexible use and various installation method.

Scope of application:

Widely used in machine tool grinding fluid, coating, paint, beer, vegetable oil, medicine, chemicals, cosmetics, petroleum products, textile chemicals, photosensitive chemicals, electroplating solution, milk, mineral water, hot flux, latex, industrial water, sugar, resin, ink, fruit juice, edible oil, wax and other industries.