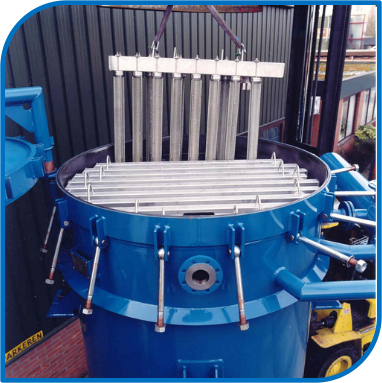

Candle Cluster Filterhousing Chemical Precision Liquid-Solid Filtration

Characteristics of cluster filter:

The pore size and distribution of the filter medium are strictly controlled, and the expensive catalyst can be 100% intercepted.

Completely closed filtration, no leakage and no environmental pollution.

The filter element design adopts compound structure (internal metal mesh support + external filter cloth).

The filter has large filtering area and large dust capacity.

It can realize one-time complete filtration.

The filter cake can be washed and dried to obtain the maximum economic benefit.

Gas back blowing is adopted for slag removal, which is clean and rapid, and is suitable for a variety of viscous materials.

The whole filtration process can be fully automated (pipeline automation configuration is adopted).

The performance of the catalyst is greatly reflected, and the catalyst can be applied repeatedly to avoid deactivation in the process of cleaning the catalyst.

It can be set as a duplex filter system with two filters (one for operation and the other for standby) and can operate continuously.

Working principle of cluster filter:

The feed liquid with catalyst enters from the outside of the filter and passes through the filter material from the outside to the inside. Impurities larger than the filter hole are intercepted and accumulated on the surface of the filter material to form a filter cake. Through bridging, the filter cake can capture some finer impurities in the water. When the impurities accumulate to a certain extent, the differential pressure rises to the set value of the system, and the inlet and outlet fluid valves are closed, The compressed gas enters and dries the filter cake. During the back blowing process, the back blowing gas discharges impurities and the filter element can be regenerated.

Cluster filter elements are mainly divided into three types: sleeved seamless filter cloth filter element, metal filter element and polymer powder sintered filter element.

Technical Parameter:

Filter area:1-200m2

OD:200-25000mm

Housing Material:304 316L CS 2205, Ti

Filtration rate:0.1-100μm

Viscosity:1-3000 cp

Tempreture:≤150℃

Design pressure:0.6-1.0 Mpa

Surface:Pickling, sandblasting, F thermoplastic Controler: PLC or Manual

Application:

Desulfurization and decarbonization

Coking wastewater treatment

PTAPVC dust recovery

Catalyst recovery

Decolorant and auxiliary filtration