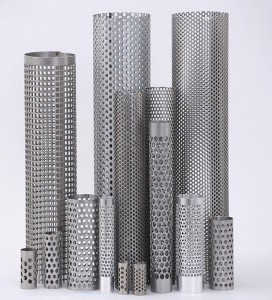

Perforated Filter Tube Products

Stainless steel perforated filter tube Information : It is perforated by stainless steel plate sheet punching machine.

Perforated Filter Tube Material: It can be divided into ordinary carbon steel plate, stainless steel , iron plate, copper , aluminum , titanium , nickel , etc.

Perforated Filter Tube Usage: For motor vehicle muffler; Pharmaceutical and paper making filtration; Battery net, packaging net, mechanical facility protection net, handicraft manufacturing, speaker net cover, decoration, children’s seat, basket, basket, road maintenance, oil tanker pedal net; Working platforms, escalators and corridors for heavy machinery, boilers, oil mines, locomotives, 10000 ton ships, etc. It is also used as reinforcement in construction industry, highway and bridge.

Perforated Filter Tube Performance characteristics :

1. The multi-layer sand control filter sleeve has sand control performance, which can better block the bottom sand particles and meet the needs of downhole killing.

2. Uniform filter holes, high permeability and anti blocking performance.

3. Large filtering area, small flow resistance and high oil yield

4. Stainless steel has excellent corrosion resistance, acid, alkali and salt corrosion resistance, which can meet the special requirements of oil wells, and the gap will not gradually become larger due to corrosion.

5. The multi-layer structure is welded into one, which can make the filter hole stable and have strong deformation resistance.

Perforated Filter Tube General dimensional parameters:

| Arrangement Mode | straight and staggered |

| Wall Thickness | 0.1-6mm |

| Aperture Range | 1-100mm |

| Width | 20-2000mm |

| Hole type | round hole, square hole, rectangular hole, plum blossom hole, triangular hole, hexagonal hole, etc |

| Surface treatment | nickel plating, silver plating, copper plating, plastic dipping, spray painting, tin plating, etc |

| Supporting customized | |

Hanke Tech has clients worldwide buying its quality wire mesh filter elements. Many of them are at the forefront in their industries offering solid and liquid filtration system. Our goal is always to provide solutions of the highest possible quality to air filter system, water treatment system and powder filter system.

Always pursuing the latest technologies, our product is made under careful quality control system of ISO 9001-2015…

Welcome your inquiry, Sincerely looking forward to serving you.