Manufacturing Companies for Perforated Stainless Tube - Perforated tube punch tube filter with different shape holes – Hanke

Manufacturing Companies for Perforated Stainless Tube - Perforated tube punch tube filter with different shape holes – Hanke Detail:

Perforated tube is made of aluminum, stainless steel, mild steel and alloy sheet.We supply perforated tube for a wide range of industries of filter elements, hydraulics, oil completion systems, etc.Then we design the plate width and punch holes customized.Then the sheets are rounded in a spiral or straight strip and welded by argon arc welding.With durable materials and different specifications,, perforated tubes can filter liquids, solids and air or sieve different materials to ensure the purity.

Margins of perforated tube: Margins are the blank (un-perforated) area along the edges of the sheet. Normally the margin on the length are 20mm minimum, and margin along the width can be 0 minimum, or at clients’ requests.

Application of perforated tube:

Filter liquids and air, such as water, oil, etc.

Filter different materials and remove impurities, such as in food, pharmaceutical, chemical and environmental protection industry.

As various support for filter elements.

Weaken the noise.

Used for granary ventilation.

Perforated tube features:

Uniform welding,acid,alkali and high pressure resistance.

Accurate roundness and straightness.

Smooth and flat surface.

Efficient filtration.

Easy to clean and long service life

Perforated tube specifications:

| material | aluminum, stainless steel, mild steel and alloy sheet |

| Thickness | 0.4–15 mm |

| Tube length: | 10–6000 mm or customized |

| Tube outside diameter | 6–200 mm |

| Wall holepattern: | round, rectangular, square, hexagonal, oval, plum blossom, etc. |

| Hole diameter | 3–10 mm |

| Open area | 23%–69% |

| Filter precision | 2–2000 μm |

| Welding process | spot welding or full welding.straight welding or spiral welding.argon arc welding |

| Surface | electrolytic polishing, galvanization, sandblasting, pickling and passivation |

| Frame structure | With or without |

| Packing | moisture-proof paper, pallet, wooden container |

| Pipe Size | Holes per feet | Size of hole | Perforated Area per Feet |

| 3/4″ | 78 | 3/16″ | 2.15 |

| 1″ | 54 | 5/16″ | 4.14 |

| 1-1/4″ | 66 | 5/16″ | 5.06 |

| 1-1/2″ | 78 | 5/16″ | 5.98 |

| 2-1/16″ | 78 | 5/16″ | 5.98 |

| 2-3/8″ | 90 | 3/8″ | 9.94 |

| 2-7/8″ | 102 | 3/8″ | 11.26 |

| 3-1/2″ | 126 | 3/8″ | 13.91 |

| 4″ | 138 | 3/8″ | 15.24 |

| 4-1/2″ | 150 | 3/8″ | 16.56 |

| 5″ | 162 | 3/8″ | 17.88 |

| 5-1/2″ | 174 | 3/8″ | 19.21 |

| 6-5/8″ | 186 | 3/8″ | 20.53 |

| 7″ | 222 | 3/8″ | 24.51 |

| 9-5/8″ | 294 | 3/8″ | 32.46 |

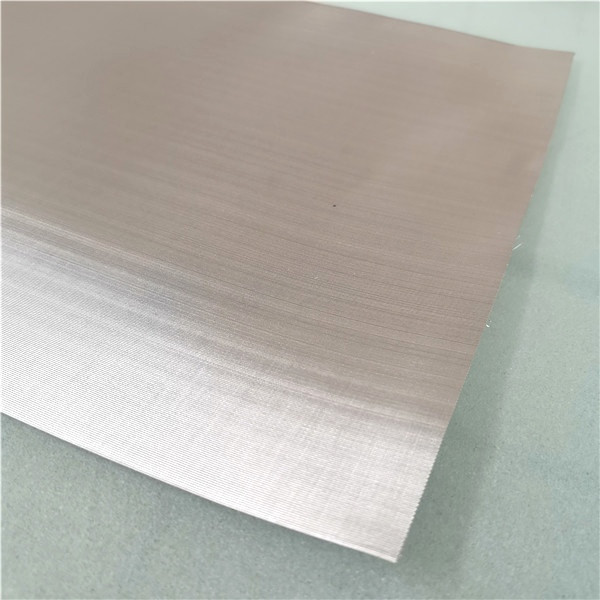

Product detail pictures:

Related Product Guide:

We offer wonderful energy in high-quality and improvement,merchandising,product sales and marketing and advertising and procedure for Manufacturing Companies for Perforated Stainless Tube - Perforated tube punch tube filter with different shape holes – Hanke , The product will supply to all over the world, such as: Kenya, Slovenia, Latvia, With the technology as the core, develop and produce high-quality products according to the diverse needs of the market. With this concept,the company will continue to develop products with high added values and continuously improve products,and will provide many customers with the best products and services!

A good manufacturers, we have cooperated twice, good quality and good service attitude.