Factory Supply Oil Filter Cone - Knitted wire mesh gas liquid filter mesh with different material – Hanke

Factory Supply Oil Filter Cone - Knitted wire mesh gas liquid filter mesh with different material – Hanke Detail:

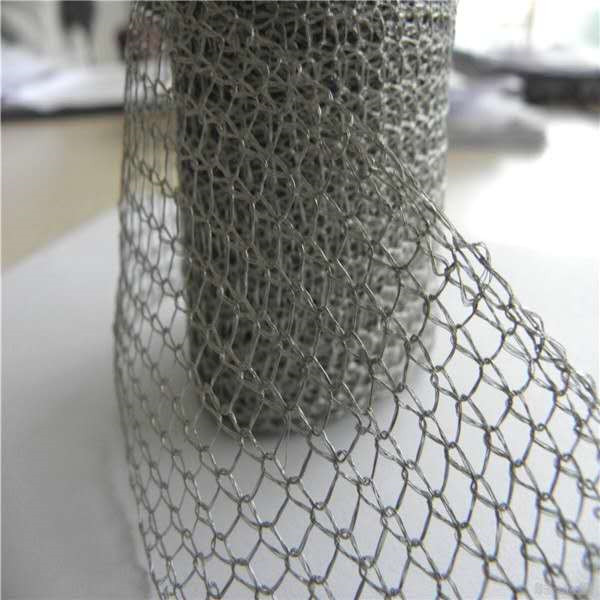

Knitted mesh-cleaner is made of metal wire, also known as gas liquid separator filter mesh,is a kind of wire mesh in a special form. Its main components used in engineering such as engine noise reduction and mechanical shock absorption, and are also widely used in the automotive industry and the electronics industry.

Wire diameter specification range: 0.08~0.3mm flat wire or round wire. Single-strand weaving, multi-strand weaving, metal wire and non-metallic wire (various fibers) weaving, etc.

Knitted mesh cleaner is the most widely used type among all material knitted meshes.

Knitted mesh cleaner can be made of mono-filament or multi-filament. Mono-filament knitted mesh is the simplest type, which can be used in the common applications and the multi-filament knitted mesh has higher strength, which can be used in the heavy duty applications.

Knitted mesh cleaner is manufactured using a knitting process where the mesh is formed from a series of interlocking loops. The original stainless steel knitted mesh is flattened when complete production, but it can be made into ginning knitted mesh by machine according to customers’ requirements. Ginning knitted mesh has different shapes, width and depth of ginning, which can suit more applications. Additional, stainless steel knitted mesh can be compressed into compressed knitted mesh for better filtering efficiency.

Specification

| Knitted mesh-cleaner / Gas Liquid Separator Filter Mesh | |

| Material | Stainless steel wire, Copper wire, Brass wire, Nickel wire, Titanium wire, Monel wire, galvanized wire, etc. |

| Woven type | Crochet weaving |

| Filament | Mono-filament, Multi-filament |

| Wire diameter | 0.08-0.5mm, normally the diameter is 0.20—0.25mm |

| Width | 40mm, 80mm, 100mm, 150mm, 200mm, 300mm, 600mm,etc |

| Hole size | 2x3mm-4x5mm-12x6mm |

| Surface type | Flattened , Ginning |

| Model | Hole amount and width | Wire diameter (mm) |

Materials | Weight (kg/m2) |

| Standard type | 40-100mm | 0.1X0.4 | 1Cr18Ni9 | 1/0.5 |

| 60-180mm | 0.1X0.4 | 1Cr18Ni9 | 1/0.5 | |

| 140-400mm | 0.1X0.4 | 1Cr18Ni9 | 1/0.5 | |

| 40-100mm | 0.27 | Galvanized Lead wire | 1/0.7 | |

| 40-100mm | 0.1X0.4 | Red copper wire | 1/0.7 | |

| Efficient type | 70-100mm | 0.1X0.3 | Stainless steel wire | 1/0.6 |

| 80-100mm | 0.1X0.3 | Stainless steel wire | 1/0.6 | |

| 90-150mm | 0.1X0.3 | Stainless steel wire | 1/0.6 | |

| 200-400mm | 0.1X0.3 | Stainless steel wire | 1/0.6 | |

| 60-100mm | 0.1X0.5 | Stainless steel wire | 1/0.6 | |

| High weaving type | 30-150mm | 0.1X0.4 | Stainless steel wire | 1/0.4 |

| 70-400mm | 0.1X0.4 | Stainless steel wire | 1/0.4 |

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority from the crucial certifications of its market for Factory Supply Oil Filter Cone - Knitted wire mesh gas liquid filter mesh with different material – Hanke , The product will supply to all over the world, such as: Orlando, Berlin, Frankfurt, Besides there are also professional production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable products quality, increase customers' satisfaction and achieve win-win situation .

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.