Factory Cheap Hot Sintered Candle Filter - Perforated tube punch tube filter with different shape holes – Hanke

Factory Cheap Hot Sintered Candle Filter - Perforated tube punch tube filter with different shape holes – Hanke Detail:

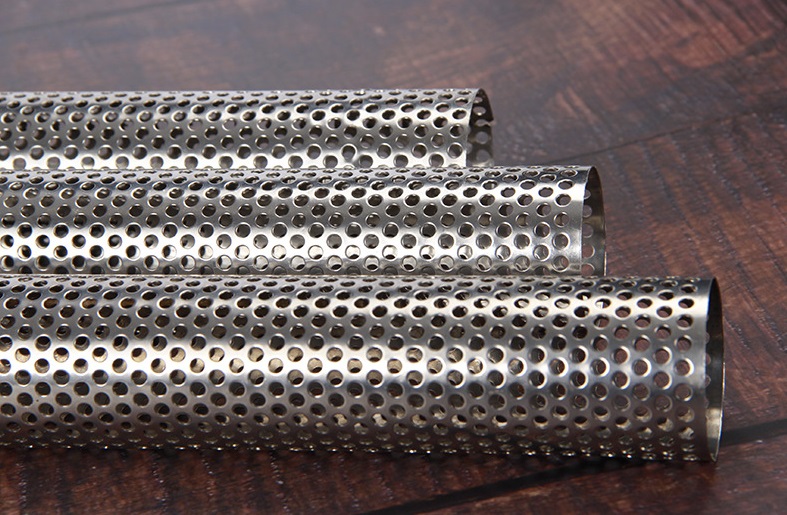

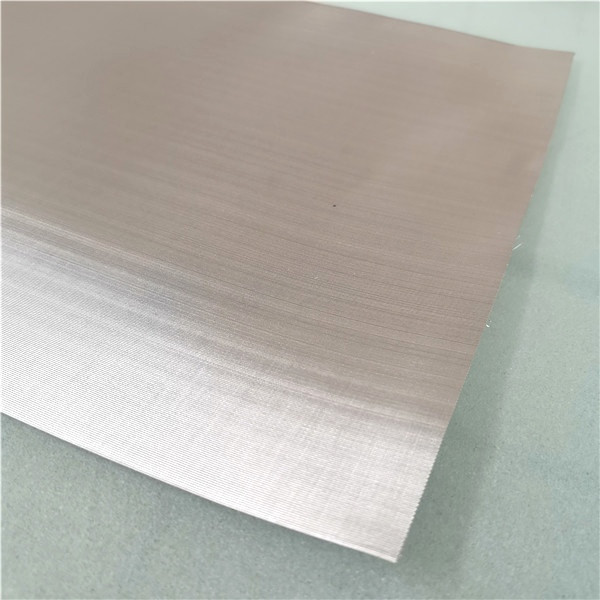

Perforated tube is made of aluminum, stainless steel, mild steel and alloy sheet.We supply perforated tube for a wide range of industries of filter elements, hydraulics, oil completion systems, etc.Then we design the plate width and punch holes customized.Then the sheets are rounded in a spiral or straight strip and welded by argon arc welding.With durable materials and different specifications,, perforated tubes can filter liquids, solids and air or sieve different materials to ensure the purity.

Margins of perforated tube: Margins are the blank (un-perforated) area along the edges of the sheet. Normally the margin on the length are 20mm minimum, and margin along the width can be 0 minimum, or at clients’ requests.

Application of perforated tube:

Filter liquids and air, such as water, oil, etc.

Filter different materials and remove impurities, such as in food, pharmaceutical, chemical and environmental protection industry.

As various support for filter elements.

Weaken the noise.

Used for granary ventilation.

Perforated tube features:

Uniform welding,acid,alkali and high pressure resistance.

Accurate roundness and straightness.

Smooth and flat surface.

Efficient filtration.

Easy to clean and long service life

Perforated tube specifications:

| material | aluminum, stainless steel, mild steel and alloy sheet |

| Thickness | 0.4–15 mm |

| Tube length: | 10–6000 mm or customized |

| Tube outside diameter | 6–200 mm |

| Wall holepattern: | round, rectangular, square, hexagonal, oval, plum blossom, etc. |

| Hole diameter | 3–10 mm |

| Open area | 23%–69% |

| Filter precision | 2–2000 μm |

| Welding process | spot welding or full welding.straight welding or spiral welding.argon arc welding |

| Surface | electrolytic polishing, galvanization, sandblasting, pickling and passivation |

| Frame structure | With or without |

| Packing | moisture-proof paper, pallet, wooden container |

| Pipe Size | Holes per feet | Size of hole | Perforated Area per Feet |

| 3/4″ | 78 | 3/16″ | 2.15 |

| 1″ | 54 | 5/16″ | 4.14 |

| 1-1/4″ | 66 | 5/16″ | 5.06 |

| 1-1/2″ | 78 | 5/16″ | 5.98 |

| 2-1/16″ | 78 | 5/16″ | 5.98 |

| 2-3/8″ | 90 | 3/8″ | 9.94 |

| 2-7/8″ | 102 | 3/8″ | 11.26 |

| 3-1/2″ | 126 | 3/8″ | 13.91 |

| 4″ | 138 | 3/8″ | 15.24 |

| 4-1/2″ | 150 | 3/8″ | 16.56 |

| 5″ | 162 | 3/8″ | 17.88 |

| 5-1/2″ | 174 | 3/8″ | 19.21 |

| 6-5/8″ | 186 | 3/8″ | 20.53 |

| 7″ | 222 | 3/8″ | 24.51 |

| 9-5/8″ | 294 | 3/8″ | 32.46 |

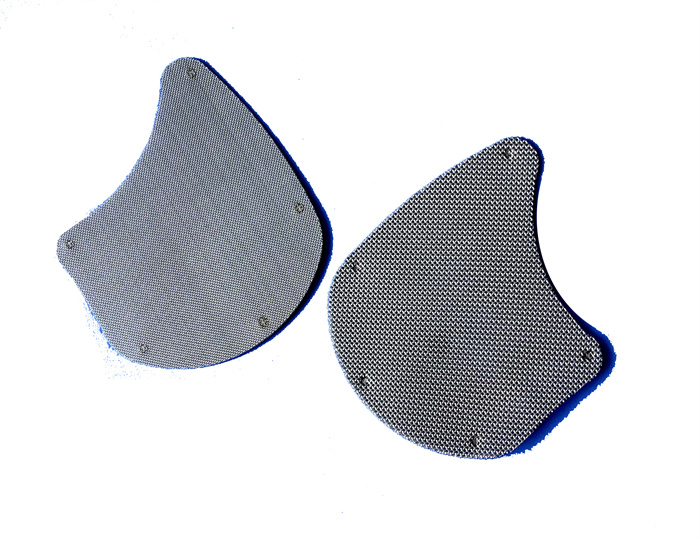

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of Factory Cheap Hot Sintered Candle Filter - Perforated tube punch tube filter with different shape holes – Hanke , The product will supply to all over the world, such as: Congo, Japan, New Zealand, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.