Bottom price Woven Mesh Fabric - Multilayer Spot Welding Extruder Screen Special shaped mesh mat polyethylene film filtration stainless steel filter packs – Hanke

Bottom price Woven Mesh Fabric - Multilayer Spot Welding Extruder Screen Special shaped mesh mat polyethylene film filtration stainless steel filter packs – Hanke Detail:

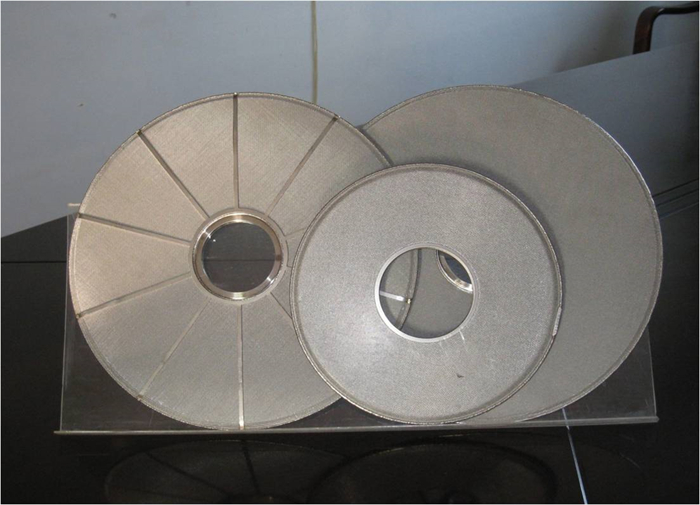

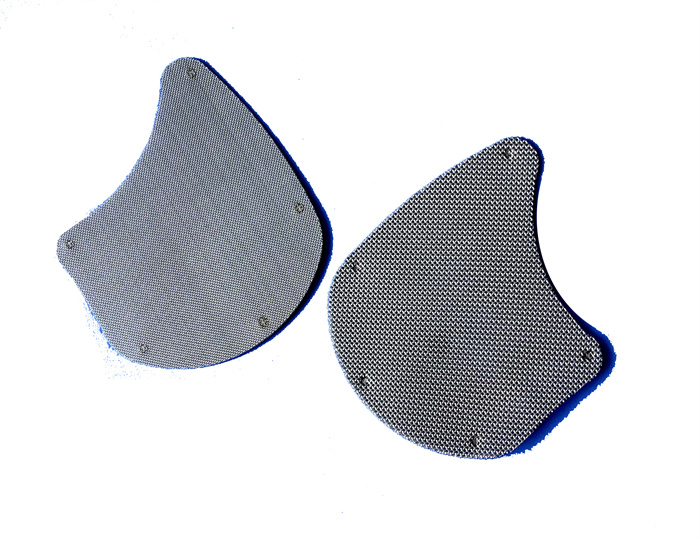

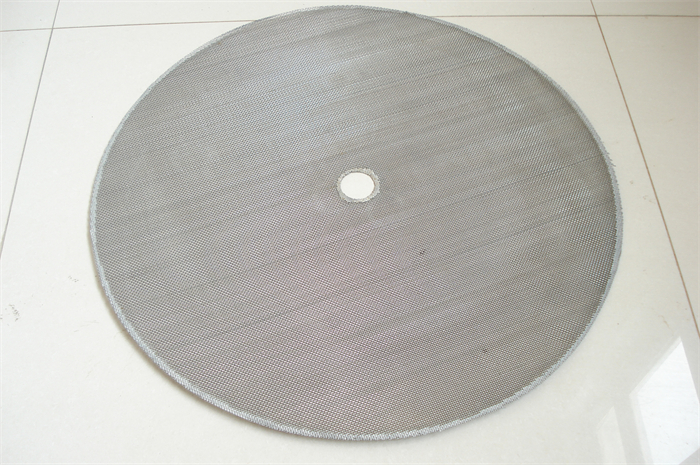

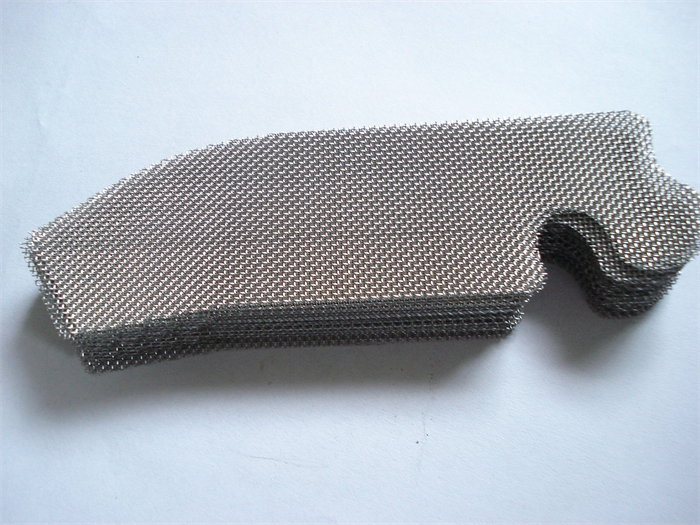

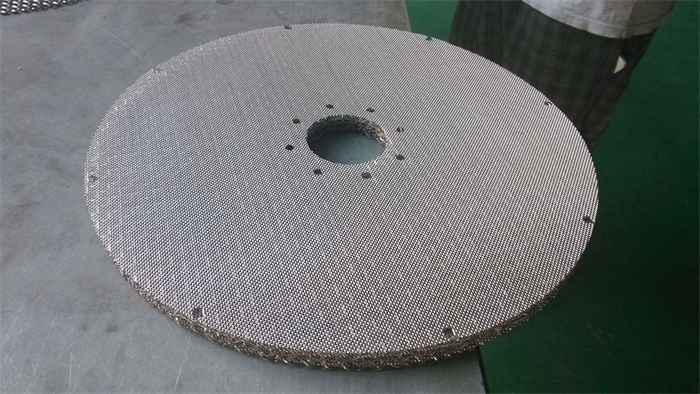

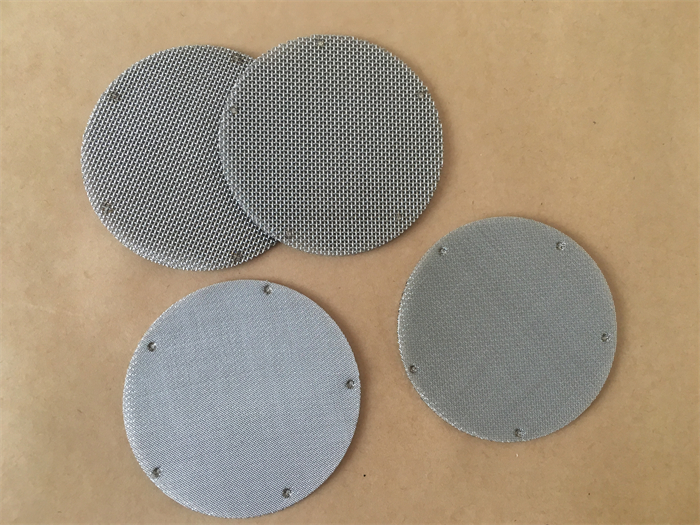

The main materials of stainless steel filter include stainless steel fiber sintered felt, stainless steel woven mesh, phosphor copper mesh, brass mesh, etc., and the edging materials include aluminum, stainless steel, copper nickel plating, etc.

The main materials of the filter are stainless steel fiber sintered felt, stainless steel woven mesh, phosphor copper mesh, brass mesh, etc., and the edging materials are aluminum, stainless steel and copper nickel plating

Wait. The filter material can be single layer or multi-layer. According to the shape, the filter is divided into circular, rectangular, waist, oval, etc.

Scope of application.: It is mainly used for impurity filtration in polyester film and chemical fiber spinning. Mainly used for the filtration and screening of gas, liquid and solid, the separation of media and so on.

With resistance for acid, alkali, high temperature and grind, it is widely used in industries like petroleum, petrochemical, automotive, new energy, food, pharmacy and others.

Square mesh: generally the wire diameter of warp and weft are the same, the mesh count of warp and weft are the same(rectangular mesh are not the same for warp and weft mesh count), weaving type can be divided into plain weave and twill weave.

Stainless steel wire mesh characteristics

1.Flat mesh surface, tightly weaved and uniform color

2. Uniform mesh opening, high and stable filtration accuracy

3. Accurate control of net weight per unit area to gram

4. Good form ability mesh surface

5. Any length can be provided by continuous loading

6. With the most advanced weaving equipment in the industry

Stainless steel wire mesh advantages

our stainless steel wire mesh products application mainly including the special used high level square mesh,used for industries like automotive, environmental protection, high-strength screening and protection, oil drilling and so on. The square mesh count ranges from 1 mesh to 635 mesh, and diameter is from 0.02~4mm, the width 0.724m~1.6m, length always 30.5m in common,and all can be customized. our high-precision fine mesh products are produced by imported looms from Germany and Japan and new intelligent NC looms independently developed. The mesh are with the characteristics of good mesh flatness, high filtration accuracy and stable performance. Precision pressure filters, fuel filters and vacuum filters made by deep processing are widely used in industries like aerospace, petroleum, chemical, fiber, rubber, metallurgy, medicine, food and so on

The main materials of stainless steel filter include stainless steel fiber sintered felt, stainless steel woven mesh, phosphor copper mesh, brass mesh, etc., and the edging materials include aluminum, stainless steel, copper nickel plating, etc.The main materials of the filter are stainless steel fiber sintered felt, stainless steel woven mesh, phosphor copper mesh, brass mesh, etc., and the edging materials are aluminum, stainless steel and copper nickel platingWait. The filter material can be single layer or multi-layer. According to the shape, the filter is divided into circular, rectangular, waist, oval, etc.Scope of application

It is mainly used for impurity filtration in polyester film and chemical fiber spinning.

Stainless steel wire mesh Prameters

|

Meshes on Linear Per inch |

Wire Diameter |

Width of Opening |

Open Area |

||

|

Inch |

mm |

Inch |

mm |

Percent |

|

|

1×1 |

.157 |

4.00 |

.84 |

21.4 |

71.0 |

|

2×2 |

.118 |

2.50 |

.38 |

10.2 |

64.0 |

|

4×4 |

.063 |

1.60 |

.187 |

4.75 |

56.0 |

|

8×8 |

0.43 |

0.71 |

.08 |

2.08 |

42.0 |

|

10×10 |

.020 |

0.50 |

.080 |

2.03 |

64.0 |

|

14×14 |

.020 |

0.50 |

.051 |

1.30 |

51.0 |

|

16×16 |

.018 |

0.22 |

.0445 |

1.13 |

50.7 |

|

18×18 |

.017 |

0.43 |

.0386 |

.98 |

48.3 |

|

20×20 |

.016 |

0.40 |

.0340 |

.86 |

46.2 |

|

30×30 |

.012 |

0.30 |

.0213 |

.54 |

40.8 |

|

40×40 |

.010 |

0.25 |

.0150 |

.38 |

36.0 |

|

50×50 |

.008 |

0.20 |

.0120 |

.31 |

36.0 |

|

60×60 |

.007 |

0.178 |

.0097 |

.25 |

33.9 |

|

80×80 |

.0055 |

0.140 |

.0070 |

.18 |

31.4 |

|

100×100 |

.004 |

0.10 |

.0060 |

.15 |

36.0 |

|

120×120 |

.0037 |

0.09 |

.0046 |

.1168 |

30.7 |

|

150×150 |

.0026 |

0.06 |

.0041 |

.1041 |

37.4 |

|

180×180 |

.0023 |

0.058 |

.0033 |

.0838 |

34.7 |

|

200×200 |

.0021 |

0.05 |

.0029 |

.0737 |

33.6 |

|

250×250 |

.0016 |

0.040 |

.0024 |

.0610 |

36.0 |

|

300×300 |

.0015 |

0.040 |

.0018 |

.0457 |

29.7 |

|

325×325 |

.0014 |

0.035 |

.0017 |

.0432 |

30.0 |

|

400×400 |

.0010 |

0.025 |

.0015 |

.0370 |

36.0 |

|

500×500 |

.0010 |

0.025 |

.0010 |

.0254 |

25.0 |

|

635×635 |

.0008 |

0.020 |

.0008 |

.0203 |

25.0 |

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product or service High quality, Reasonable Rate and Efficient Service" for Bottom price Woven Mesh Fabric - Multilayer Spot Welding Extruder Screen Special shaped mesh mat polyethylene film filtration stainless steel filter packs – Hanke , The product will supply to all over the world, such as: Armenia, Manila, Greece, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.