Manufacturer of Warp Knit Mesh - Knitted wire mesh gas liquid filter mesh with different material – Hanke

Manufacturer of Warp Knit Mesh - Knitted wire mesh gas liquid filter mesh with different material – Hanke Detail:

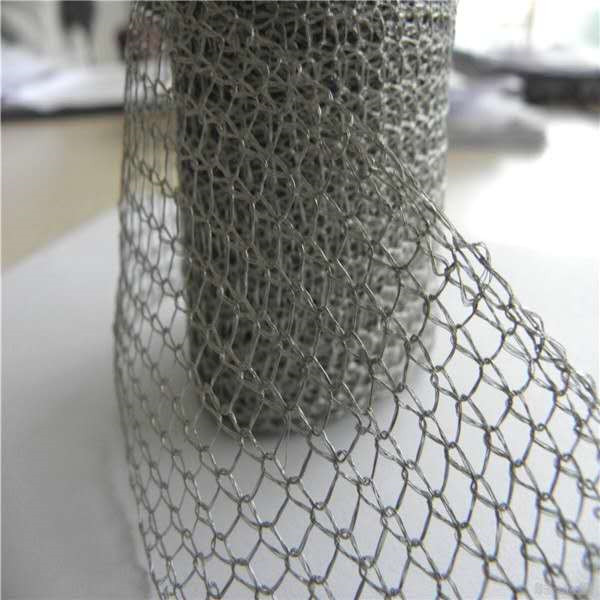

Knitted mesh-cleaner is made of metal wire, also known as gas liquid separator filter mesh,is a kind of wire mesh in a special form. Its main components used in engineering such as engine noise reduction and mechanical shock absorption, and are also widely used in the automotive industry and the electronics industry.

Wire diameter specification range: 0.08~0.3mm flat wire or round wire. Single-strand weaving, multi-strand weaving, metal wire and non-metallic wire (various fibers) weaving, etc.

Knitted mesh cleaner is the most widely used type among all material knitted meshes.

Knitted mesh cleaner can be made of mono-filament or multi-filament. Mono-filament knitted mesh is the simplest type, which can be used in the common applications and the multi-filament knitted mesh has higher strength, which can be used in the heavy duty applications.

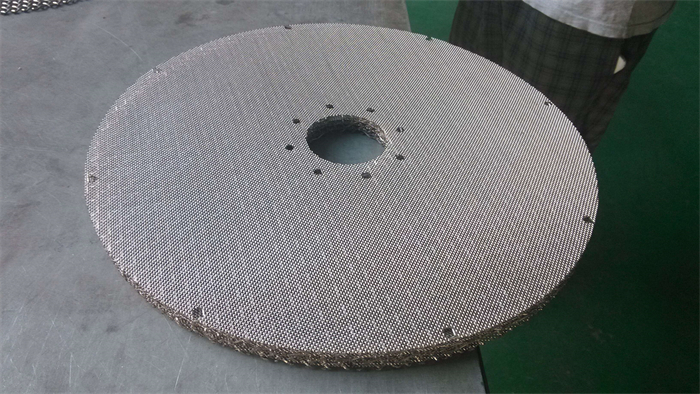

Knitted mesh cleaner is manufactured using a knitting process where the mesh is formed from a series of interlocking loops. The original stainless steel knitted mesh is flattened when complete production, but it can be made into ginning knitted mesh by machine according to customers’ requirements. Ginning knitted mesh has different shapes, width and depth of ginning, which can suit more applications. Additional, stainless steel knitted mesh can be compressed into compressed knitted mesh for better filtering efficiency.

Specification

| Knitted mesh-cleaner / Gas Liquid Separator Filter Mesh | |

| Material | Stainless steel wire, Copper wire, Brass wire, Nickel wire, Titanium wire, Monel wire, galvanized wire, etc. |

| Woven type | Crochet weaving |

| Filament | Mono-filament, Multi-filament |

| Wire diameter | 0.08-0.5mm, normally the diameter is 0.20—0.25mm |

| Width | 40mm, 80mm, 100mm, 150mm, 200mm, 300mm, 600mm,etc |

| Hole size | 2x3mm-4x5mm-12x6mm |

| Surface type | Flattened , Ginning |

| Model | Hole amount and width | Wire diameter (mm) |

Materials | Weight (kg/m2) |

| Standard type | 40-100mm | 0.1X0.4 | 1Cr18Ni9 | 1/0.5 |

| 60-180mm | 0.1X0.4 | 1Cr18Ni9 | 1/0.5 | |

| 140-400mm | 0.1X0.4 | 1Cr18Ni9 | 1/0.5 | |

| 40-100mm | 0.27 | Galvanized Lead wire | 1/0.7 | |

| 40-100mm | 0.1X0.4 | Red copper wire | 1/0.7 | |

| Efficient type | 70-100mm | 0.1X0.3 | Stainless steel wire | 1/0.6 |

| 80-100mm | 0.1X0.3 | Stainless steel wire | 1/0.6 | |

| 90-150mm | 0.1X0.3 | Stainless steel wire | 1/0.6 | |

| 200-400mm | 0.1X0.3 | Stainless steel wire | 1/0.6 | |

| 60-100mm | 0.1X0.5 | Stainless steel wire | 1/0.6 | |

| High weaving type | 30-150mm | 0.1X0.4 | Stainless steel wire | 1/0.4 |

| 70-400mm | 0.1X0.4 | Stainless steel wire | 1/0.4 |

Product detail pictures:

Related Product Guide:

Excellent 1st,and Client Supreme is our guideline to deliver the ideal provider to our prospects.Nowadays, we have been seeking our best to become certainly one of the most effective exporters in our discipline to meet shoppers more require for Manufacturer of Warp Knit Mesh - Knitted wire mesh gas liquid filter mesh with different material – Hanke , The product will supply to all over the world, such as: UAE, Austria, Jeddah, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!