Hot sale Stainless Steel Screening Mesh - Cone filter temporary filter with sintered mesh,woven mesh or perforated mesh – Hanke

Hot sale Stainless Steel Screening Mesh - Cone filter temporary filter with sintered mesh,woven mesh or perforated mesh – Hanke Detail:

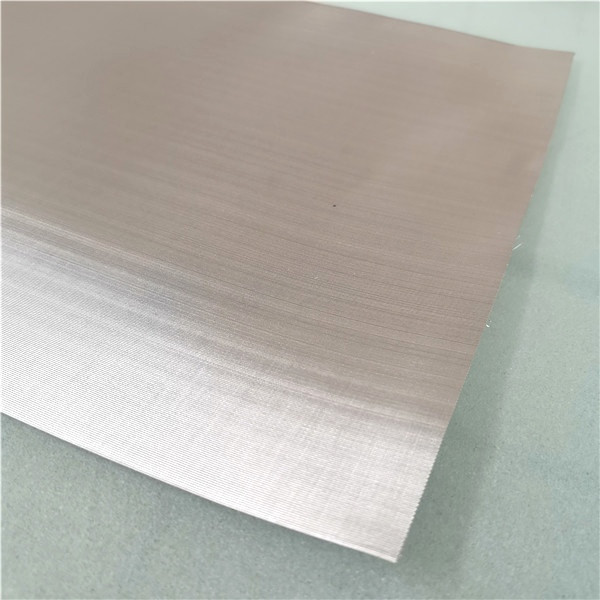

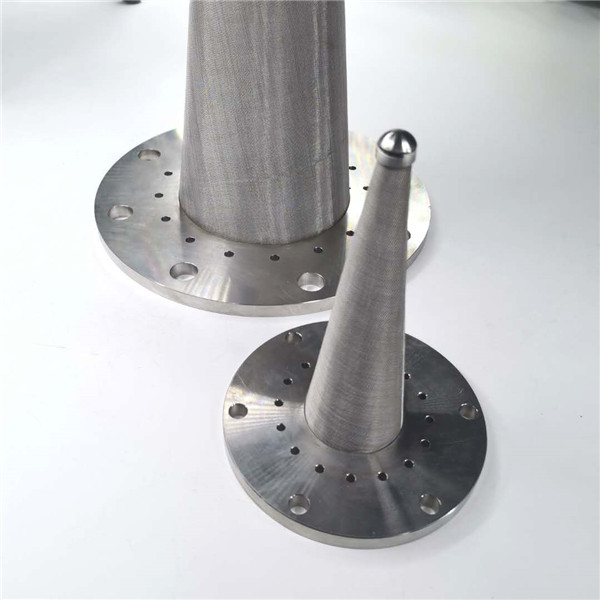

cone filter is also known as temporary conical filter made of sintered mesh,perforated mesh or woven mesh.

The filter is a design that extends on the basis of the filter plate,it is increased the filtration area,and easy to unload.It is designed to offer good protection for expensive pumps,values meters and other mechanical equipment.

These filters can be manufactured in various sizes and specifications, using a wide variety of materials. Usually placed inline in a fluid stream, they are generally used for high-velocity fluid flow applications.

Their design includes a perforated cone supporting one or more fine wire meshes, as per the filtration requirement. flat hat strainers are the most common type of conical filters used in industry, due to their well-established design and effective filtration qualities.

Material:the standard material are SS304,SS304L,SS316,SS316L,other material is available for customer requirement

Specification below is needed to quote:(best with drawing)

Handle size

Flange thickness

End connection

Open area

Installation instructions

Put gas filter between two flanges

Two gaskets should be fitted on two sides

Fasten bolts,make sure filter is in the precise position

Application

Coiling,drying

Transporting and filtering solid particles in chemical,pharmaceutical,pesticide and food industries

Cone filter Sintered wire mesh specification:

| Model | Nominal Rating μm |

Structure | Thickness mm | AirPermeability l/min/cm2 |

Bubble Point Pressure mmH20 |

| A5-1 | 1 | 200+400×3000+200+12×64+64×12 | 1.7 | 1.81 | 360-600 |

| A5-2 | 2 | 100+325×2300+100+12×64+64×12 | 1.7 | 2.35 | 300-590 |

| A5-5 | 5 | 100+200×1400+100+12×64+64×12 | 1.7 | 2.42 | 260-550 |

| A5-10 | 10 | 100+165×1400+100+12×64+64×12 | 1.7 | 3.00 | 220-500 |

| A5-15 | 15 | 100+165×1200+100+12×64+64×12 | 1.7 | 3.41 | 200-480 |

| A5-20 | 20 | 100+165×800+100+12×64+64×12 | 1.7 | 4.50 | 170-450 |

| A5-25 | 25 | 100+165×600+100+12×64+64×12 | 1.7 | 6.12 | 150-410 |

| A5-30 | 30 | 100+400+100+12×64+64×12 | 1.7 | 6.70 | 120-390 |

| A5-40 | 40 | 100+325+100+12×64+64×12 | 1.7 | 6.86 | 100-350 |

| A5-50 | 50 | 100+250+100+12×64+64×12 | 1.7 | 8.41 | 90-300 |

| A5-75 | 75 | 100+200+100+12×64+64×12 | 1.7 | 8.70 | 80-250 |

| A5-100 | 100 | 100+150+100+12×64+64×12 | 1.7 | 9.10 | 70-190 |

| Thickness: 1.7(mm); Porosity : ~37%;Weight kg/m²: 5-layers sintered wire mesh (8.4) 6-layers sintered wire mesh (14.4)6-layers construction adds additional 12 mesh to ordinary 5-layers mesh for better pressure resistance, thus thickness reaches 3.5mm. | |||||

Product detail pictures:

Related Product Guide:

We provide good power in high-quality and progress,merchandising,revenue and internet marketing and operation for Hot sale Stainless Steel Screening Mesh - Cone filter temporary filter with sintered mesh,woven mesh or perforated mesh – Hanke , The product will supply to all over the world, such as: Malawi, Cyprus, Madrid, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products and solutions for our customers.

We have been looking for a professional and responsible supplier, and now we find it.