China OEM Self Cleaning Filters For Liquids - Self-cleaning filter filter housing for water with stainless steel material – Hanke

China OEM Self Cleaning Filters For Liquids - Self-cleaning filter filter housing for water with stainless steel material – Hanke Detail:

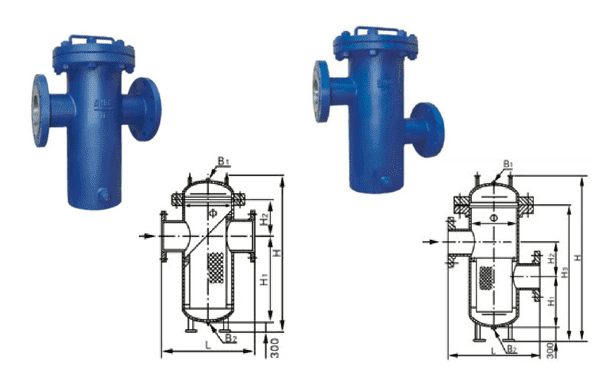

Self-cleaning filter also name filter housing/filtration system,consists of vertical cylindrical body,sealing cap,flange,connection plat etc. inside may choose the different filtration rate of filter element. The connection method may be many kinds of shapes such as bayonet and thread connection. Filtration rate and connection method are available according to clients process requirement. Filter material is SUS304 ,SUS316LHastelloy alloy. Internal surface is polished, passivated by acid liquid and no dead angle.

Self-cleaning filter working principle

The filter will start the cleaning process when differential pressure of inlet and outlet reaches the preset value. The whole self-cleaning process contains two steps: the drain valve on the end cover of the filter opens; the two stainless steel brushes in ontology mesh is driven by motor inside, then the impurities which is captured by mesh will be brushed by the steel brush and will be discharged from the drain valve.The whole cleaning process takes about 15 to 60 seconds, During this time, the filtration system does not stop and the whole operation process is completed by a control box.

Benefit

Safeguard the health and safety of your operators – With a completely enclosed system, no hazardous product such as fumes can escape while also limiting operator exposure of your liquid products.

Increase your production rates – With its self-cleaning design there are no stoppages to change filter media, resulting in consistent and reliable filtration.

Improve your product quality – The enclosed system eliminates the risk of contamination entering your production line.

Reduce waste and operation costs – The self-cleaning filter eliminates the need for replacing filter media and disposal costs, reducing product wastage, labor costs and downtime.

application

1. Steel: used for water treatment filtration in raw material field, sintering pellet plant, cooling water filtration of blast furnace, rolling mill, continuous casting machine and other systems, and impurity filtration of high-pressure water phosphorus removal system.

2. Automobiles: coating production lines are widely used in water treatment systems for automobiles, tractors, motorcycles, and engines.

3. Power plant: It is used for the precision pretreatment part of high-purity water preparation of power plant boilers, the filtration of generator cooling water and sealing water, and the system 13-4 can be used as a side filter when the water consumption is extremely large.

4. Petrochemical industry: in the circulating water field for side filtration treatment, single or multiple models can be connected in parallel for main treatment instead of filter material filtration, reducing filter material filtration load, avoiding a large amount of washing water consumption and saving costs.

5. Agricultural gardens and paper mills: In sprinklers and nozzle systems, equipment blockage and wear caused by impurities should be reduced. Therefore, it is necessary to choose high-precision, high-automated filtration products, machinery, food or other: automatic and precise Filtering to prevent clogging of the cooling water system.

| Self cleaning filter general parameters | |

| Operation flow rate | 20-5000m3/hDifferent water quality and filter precision have different flow rate customized |

| Working pressure | 2bar-10barBooster pump equipment can be set in drain outlet when the when the the working pressure is low |

| Drain valve Size | 25mm; 50mm; 80mm |

| Cleaning time | 30-60S |

| Cleaning water consumption (every time) | ≤5% |

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for China OEM Self Cleaning Filters For Liquids - Self-cleaning filter filter housing for water with stainless steel material – Hanke , The product will supply to all over the world, such as: panama, Zimbabwe, Bangkok, We have to continue to uphold the "quality, comprehensive, efficient" business philosophy of "honest, responsible, innovative"spirit of service, abide by the contract and abide by reputation, first-class products and improve service welcome overseas customers patrons.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.